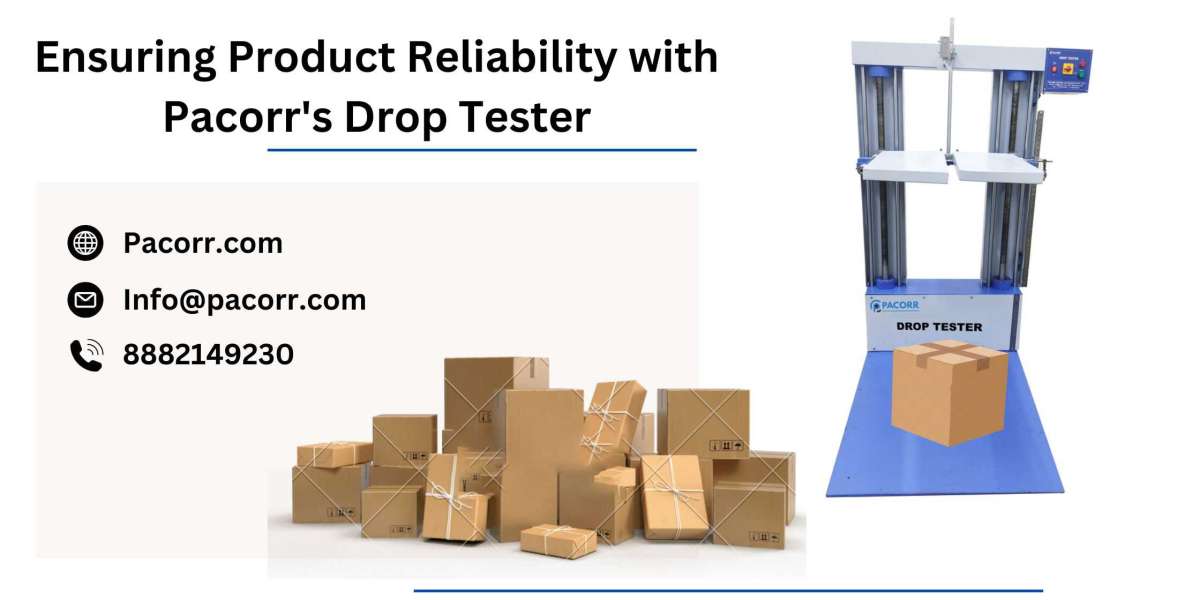

At Pacorr, we understand the significance of precise testing methods, and our drop testers are engineered to provide accurate results that can save both time and resources in the long run.

What is a Drop Tester?

A Drop Tester is a specialized piece of equipment designed to assess the strength and durability of packaging materials by simulating the conditions they might face during transportation and handling. The tester works by dropping a package from a specified height onto a hard surface, replicating the impact that the package may encounter during real-world scenarios. The results from these tests are crucial in determining whether a package can adequately protect its contents from damage during its journey from manufacturer to consumer.

Why is Drop Testing Essential?

Drop Testing is a vital aspect of quality control in the packaging industry. It helps manufacturers ensure that their packaging can withstand the stresses of handling, transportation, and storage. Here are a few reasons why drop testing is indispensable:

- Preventing Product Damage: Drop testing helps identify weaknesses in packaging that could lead to product damage. By addressing these issues early in the design process, manufacturers can avoid costly recalls and returns.

- Compliance with Standards: Many industries have strict regulations regarding packaging strength and durability. Drop testing ensures that packaging meets these standards, helping companies avoid legal issues and maintain their reputation.

- Cost Savings: Identifying and correcting packaging weaknesses early in the production process can lead to significant cost savings. By preventing damage to products, companies can reduce waste and improve their bottom line.

- Customer Satisfaction: Robust packaging reduces the likelihood of product damage during shipping, leading to higher customer satisfaction and fewer complaints.

Features of Pacorr’s Drop Testers

Pacorr’s Drop Tester Price are designed to meet the rigorous demands of modern packaging testing. Here are some of the key features of our drop testers:

- Versatile Testing Capabilities: Pacorr’s drop testers can be adjusted to accommodate a wide range of package sizes and weights, making them suitable for various industries, from electronics to food and beverage.

- High Precision: Our drop testers are equipped with advanced technology to ensure precise control over drop height and impact angle. This level of accuracy is crucial for obtaining reliable test results.

- User-Friendly Design: Pacorr’s drop testers are designed with ease of use in mind. They feature intuitive controls and clear displays, making them accessible to operators of all skill levels.

- Durability and Reliability: Built with high-quality materials, our drop testers are engineered for long-term use, providing consistent performance even in demanding testing environments.

Applications of Drop Testing

Drop Impact Tester is used across various industries to ensure that packaging can protect products effectively. Some common applications include:

- Consumer Electronics: Ensuring that delicate electronics, such as smartphones and laptops, are not damaged during shipping.

- Food and Beverage: Verifying that packaging for fragile items like glass bottles can withstand drops without breaking.

- Pharmaceuticals: Ensuring that medical supplies and equipment are delivered safely without compromising their integrity.

- Automotive Parts: Testing packaging for heavy or irregularly shaped automotive components to ensure they arrive intact.

Conclusion

In an era where packaging must be both functional and cost-effective, Drop Tester provides the insights needed to optimize design and materials. At Pacorr, we are committed to providing our clients with reliable testing equipment that delivers accurate results, helping them maintain the highest standards of quality and customer satisfaction.