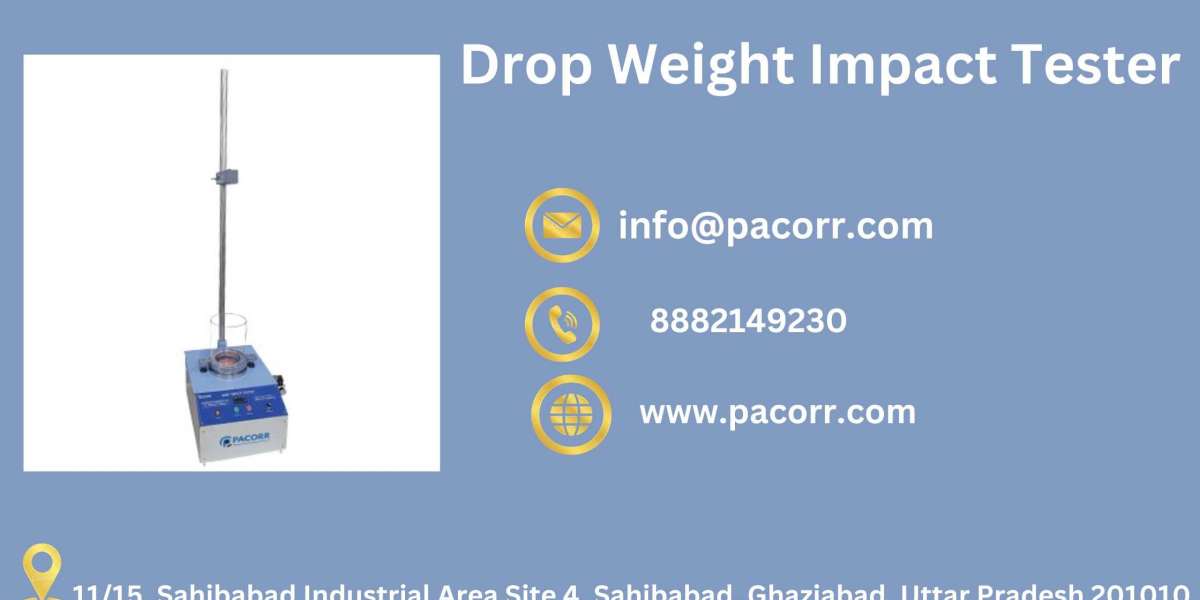

Exploring the Drop Weight Impact Tester: Ensuring Product Durability with Precision Testing

In today's competitive market, ensuring the durability and reliability of products is paramount. Manufacturers must guarantee that their products can withstand real-world conditions and maintain their integrity throughout their lifecycle. This is where the Drop Weight Impact Tester from Pacorr Testing Instruments comes into play. This article delves into the significance of the Drop Weight Impact Tester and how it aids manufacturers in achieving high-quality standards.

What is a Drop Weight Impact Tester?

The Drop Weight Impact Tester Price is a specialized testing device used to evaluate the impact resistance of materials and products. It simulates the conditions that products might encounter during transportation, handling, and usage. By replicating these impacts, manufacturers can predict the performance and durability of their products under various scenarios.

Key Features and Benefits

- Precision Testing: The Drop Weight Impact Tester offers precise control over the impact parameters, including weight, height, and speed of the drop. This ensures consistent and repeatable testing results, providing manufacturers with reliable data.

- Versatility: This testing equipment can be used on a wide range of materials, from plastics and metals to composites and ceramics. Its adaptability makes it a valuable tool for various industries, including automotive, aerospace, packaging, and consumer goods.

- Customization: Pacorr's Drop Weight Impact Testing can be tailored to meet specific testing requirements. Manufacturers can adjust the settings to mimic different real-world conditions, ensuring comprehensive testing for diverse applications.

- Data Accuracy: Equipped with advanced sensors and data acquisition systems, the Drop Weight Impact Tester captures detailed information about the impact event. This data is crucial for analyzing the material's response to impact and making informed decisions about product design and improvement.

- Safety and Compliance: Using the Drop Weight Impact Tester helps manufacturers comply with international standards and regulations. By ensuring that products meet these standards, companies can avoid costly recalls and enhance their reputation for quality and safety.

Applications of the Drop Weight Impact Tester

- Automotive Industry: In the automotive sector, components such as bumpers, dashboards, and interior panels must withstand impact forces during collisions. The Drop Weight Impact Tester helps engineers design safer and more resilient vehicle parts.

- Aerospace Industry: Aerospace materials, including composites used in aircraft structures, require rigorous testing to ensure they can endure impact forces during flight and landing. The tester provides valuable data for enhancing the safety and performance of aerospace components.

- Packaging Industry: Packaging materials must protect contents from damage during transit. The Drop Weight Impact Tester evaluates the robustness of packaging solutions, ensuring that products reach consumers in perfect condition.

- Consumer Goods: Household items, electronics, and toys must endure drops and impacts in everyday use. This testing equipment helps manufacturers create durable and reliable products that can withstand accidental drops.

How the Drop Weight Impact Tester Works

The Drop Weight Impact Teste operates by dropping a specified weight from a predetermined height onto the test specimen. The impact energy is transferred to the specimen, simulating real-world conditions. The equipment measures the force, deformation, and other critical parameters during the impact event. This data is then analyzed to determine the material's resistance to impact and identify potential areas for improvement.

Conclusion

The Drop Weight Impact Testing is an indispensable tool for manufacturers striving to produce high-quality, durable products. By providing precise and reliable impact testing, it helps industries enhance product performance, ensure safety, and comply with international standards. Pacorr Testing Instruments' commitment to innovation and quality makes their Drop Weight Impact Tester a trusted choice for manufacturers worldwide.